Health & Safety

Altrad Belle are No.1 for Low Hand Arm Vibration Products

Since machine to user vibration was first identified as a significant problem to the user’s health, ALTRAD Belle have sought to reduce exposure. Altrad Belle engineers have reduced operator vibration on Rammers, Floor Saws and Plate Compactors without reducing effectiveness.

The PCX range of eight hour plus, single direction plate compactors for example, represent our latest vibration control plates. They feature vibration reducing frames, unique base plates, handle isolators and tuned vibrators which deliver class leading performance.

OPERC Independent Testing

The Off-Highway Plant and Equipment Research Centre is an independent testing laboratory which leads the construction industries efforts to measure Hand Arm Vibration exposure.

HAVTEC is the OPERC vibration testing facility. It provides independent assessment of the hand-arm vibration (HAV) exposure that an operator will be exposed to from the use of mechanical hand-held power tools.

The results of the tests are recorded on the HAVTEC register, which is made available through the OPERC website:- www.operc.com/havtec/

Altrad Belle has submitted a number of products for independent scrutiny including single direction plates, hydraulic breakers and floor saws. OPERC have now published these results on their HAVTEC website.

What is Hand Arm Vibration?

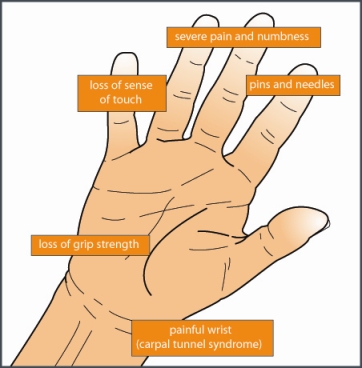

Hand Arm Vibration Syndrome is the term used to describe medical conditions caused by hand held tools that induce vibration in the user. These medical conditions include Carpal Tunnel Syndrome, Vibration White Finger, impaired blood flow in the hands, reduced strength in the arms and fingers and increase sensitivity. Early symptoms include finger numbing, pins and needles but can progress to pain in the wrists, arms, elbows and shoulders followed by nerve damage, bone and joint disorders and in extreme situations cause gangrene. The damage caused is cumulative, that is to say that continuous daily use of hand held vibrating equipment increases the risk of the user developing symptoms.

The Governments Regulations

The government through the Health and Safety Executive has issued guideline exposure levels for Hand Arm Vibration in the form of The Control of Vibration at Work Regulations 2005 (the Vibration Regulations).

The regulation-guidelines state that by 2010, use of vibrating hand-held tools should be strictly limited and where used the tools should perform within guideline values. By law an employer must assess and identify measures to eliminate or reduce risk. Examples of good practice can be found on the HSE website at: www.hse.gov.uk/vibration.

The regulations introduce an Exposure Action Value Limit (EAV) beyond which work rotation is required and an upper limit known as the Exposure Limit Value (ELV) beyond which hand held devices should not be used.

|

|

Exposure Action Value (EAV) and Exposure Limit Value (ELV)

The Exposure Action Value is the daily limit to which an employee can be exposed before an employer has to undertake actions to reduce the risk of Hand Arm Vibration.

Beyond the daily Exposure Action Value of 2.5m/s² the employer must assess the risk to the employee, introduce a programme of controls, provide a health screening programme, plus provide information and training on the risk to the employee’s health and actions to take to reduce exposure.

The Exposure Limit Value (ELV) is the daily maximum amount of vibration an employee can be exposed to. This upper limit will be fully enforced after July 2010 and the transitional period applies to equipment purchased before July 2007. The upper limit can be exceeded during the transition period only after all practicable actions to reduce exposure have been exhausted.

The types of hand-tools that are likely to be of concern include road breakers, cut-off saws, rammers, rotary-hammer drills, demolition hammers, plate compactors, floor saws, scabblers, angle grinders and needle scalers. If an employee is likely to be using several vibration risk tools during their working day then the employer must collect information on the likely personal exposure and trigger time for each tool. Once collected the employer should use the vibration data and exposure times and apply an exposure calculator.

For example, see HSE’s vibration web site www.hse.gov.uk/vibration. Alternatively, there is a points system:-

| Tool vibration (m/s²) | 3 | 4 | 5 | 6 | 7 | 10 | 12 | 15 |

| Points per hour (approx) | 20 | 30 | 50 | 70 | 100 | 200 | 300 | 450 |

Multiply the points assigned to the tool vibration by the number of hours of daily ‘trigger time’ for the tool(s) and then compare the total with the exposure action value (EAV) and exposure limit value (ELV) points.

100 points per day = Exposure Action Value (EAV)

400 points per day = Exposure Limit Value (ELV)

The above is for guidance only and employers/employees should consult with their own Health and Safety experts for further clarification.

| Model | Part Number | HAV Level (m/s²) | Trigger time to reach EAV level 2.5 | Trigger time to reach ELV level 5.0 | Weight (kg) |

|---|---|---|---|---|---|

| PCEL 320X Honda | ELX3201 | 4.43 m/s²** | 2 hours 33 mins | 10 hours 11mins | 49 |

| PCLX 320 Honda | LC3251 | 2.42 m/s²** | 8 hours 32 mins | More than 24 hours | 59 |

| PCLX 400 Honda | LC4051 | 2.48 m/s²** | 8 hours 8 mins | More than 24 hours | 64 |

| PCLX 320 Streetworks | LX3251 | 2.14 m/s²** | 10 hours 55 mins | More than 24 hours | 65 |

| PCX 12/36 Honda | FC3600E | 4.74 m/s²** | 2 hours 14 mins | 8 hours 54 mins | 81 |

| PCX 13/40 Honda | FC4000E | 3.20 m/s²** | 4 hours 53 mins | 19 hours 32 mins | 83.5 |

| PCX 450 Honda | PC4500 | 1.90 m/s²** | 13 hours 35 mins | More than 24 hours | 86 |

| PCX 500 Honda | PC5000 | 2.00 m/s²** | 12 hours 4 mins | More than 24 hours | 88 |

| Compact 350X Honda | CSXA01 | 2.80 m/s²** | 6 hours 31 mins | More than 24 hours | 96 |

| BHB 25X Breaker | BHB25XS | 6.50 m/s²** | 1 hour 11 mins | 4 hours 44 mins | 25 |

**OPERC independent testing/Vibration levels tested to BS5349 using EN 500-4